Your specialist for process automation

– Efficiency through intelligent processes

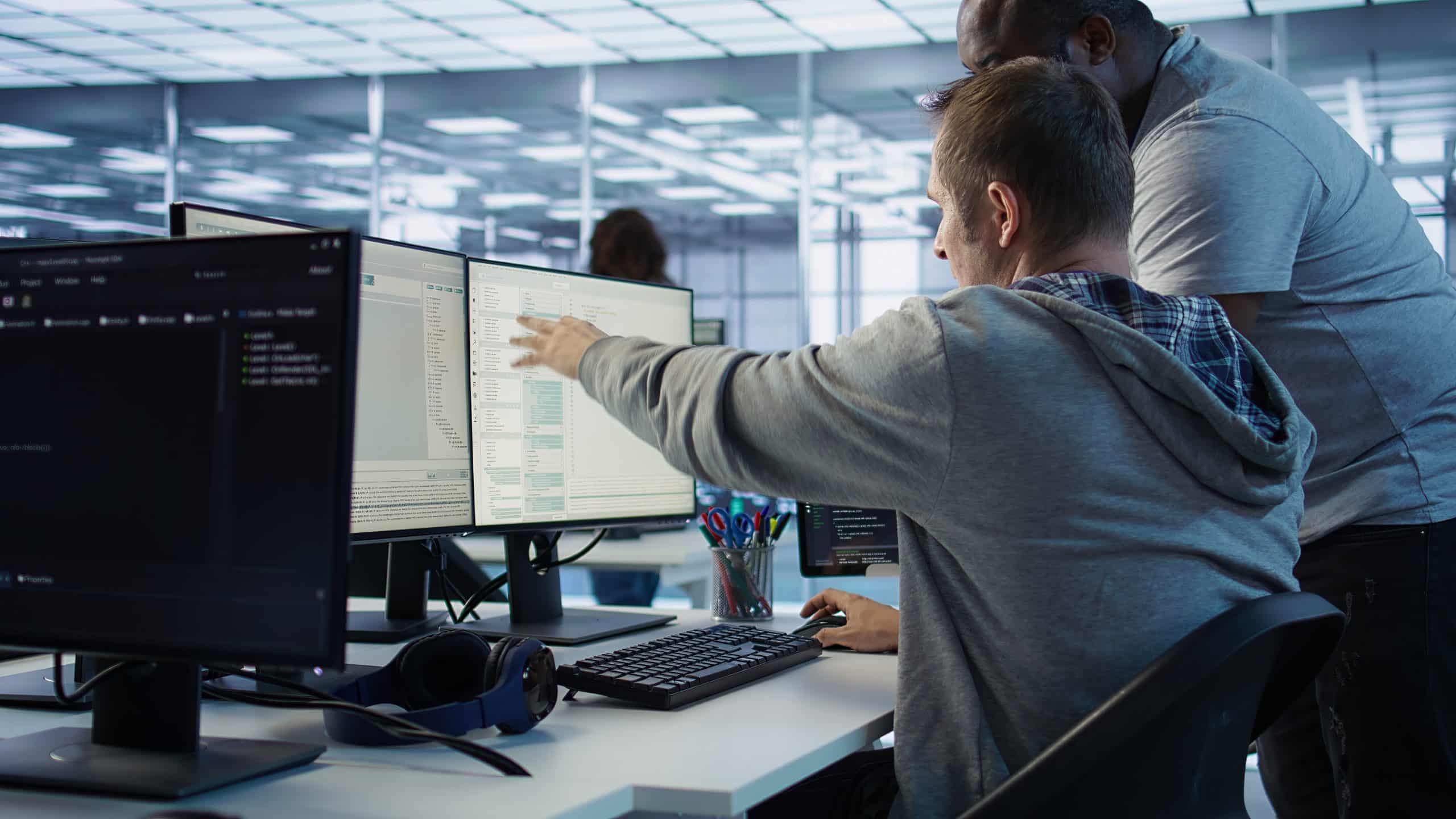

Industrial IT Solutions are digital technologies and platforms that intelligently combine IT and automation. The aim is to make processes more transparent, efficient and future-proof – from central data management to virtual simulations.

Our portfolio includes PCS 7 virtualization, COMOS as a Service, the Digital Twin and Industrial IoT and cloud solutions via our partner company HUBSTER.S.

Customers gain more transparency about their processes, greater system availability and the ability to make data-based decisions in real time. Project lead times are also shortened and operating costs reduced.

HUBSTER.S provides cloud and IIoT solutions for collecting and analyzing production data, while XRify enables simulation, training and virtual commissioning with Digital Twin and XR technologies. Together, they create innovative and end-to-end digitalization solutions.

Our solutions are used across all industries – from industrial production to food & beverage, minerals and pharmaceuticals – wherever digital technologies make processes smarter.